Furnace Not Heating? DIY Troubleshooting Steps to Stay Warm

A furnace that runs but doesn’t warm your home feels urgent — especially in the middle of winter. This guide walks through the most likely reasons a furnace won’t heat and gives safe, practical checks you can do yourself. We cover the thermostat, air filter, ignitor and pilot, flame sensor, blower motor, and ductwork, plus step-by-step troubleshooting for cold-air problems, ignition failures, short cycling, and when it’s time to stop and call a pro. Each check links a symptom to a likely cause so you can narrow the issue faster. Read on for quick-reference tables, numbered troubleshooting steps, and simple maintenance tips to help prevent repeat problems and keep your system running efficiently.

Puckett’s Heating & Air is a local HVAC team serving homeowners and small commercial customers across Maryland and Delaware. We repair, replace, install, and maintain furnaces — and we always look at the whole duct system when we evaluate a job. Our approach is straightforward and customer-first; our technicians hold certifications such as BPI, Energy Star Rater, HERS Rater, and NCI for air balancing. If you complete the homeowner checks below and want a professional inspection, Puckett’s can test combustion and airflow, inspect parts, and recommend repair versus replacement.

What Are the Most Common Reasons My Furnace Is Not Heating?

When a furnace produces no heat, the cause usually falls into one of four areas: airflow, controls, ignition/combustion, or power. A dirty filter or closed vents reduce airflow and can trigger safety shutoffs. Thermostat settings or wiring errors stop the call for heat. Ignition parts like the ignitor or pilot may fail to light burners, and electrical or gas interruptions prevent the unit from running. Knowing these categories helps you triage the problem and run safe checks that point to the underlying cause. Below is a short list of the most frequent problems and what to look for at home.

Common causes that lead to a furnace not heating:

- Dirty or clogged air filter: Cuts airflow, can cause overheating and trigger the limit switch.

- Thermostat misconfiguration or dead batteries: Stops the furnace from getting a valid heat call.

- Power interruption or tripped breaker: The control board and blower won’t run without power.

- Ignitor or pilot failure: No flame means no heat, even if the fan runs.

- Gas supply or valve issue: No fuel equals no combustion; safety systems may lock the unit out.

- Blower motor or capacitor failure: The furnace can’t move warm air through the ducts.

Use this list for quick triage. The table below links common components with likely symptoms and easy checks you can perform safely to see what’s most likely at fault.

| Component | Symptom / Attribute | Likely Cause / Quick Check |

|---|---|---|

| Air filter | Reduced airflow, long run times | Look at the filter — replace or clean if it’s dirty or clogged |

| Thermostat | No heat call, incorrect display | Make sure mode is set to “Heat”, setpoint is above room temp, and batteries are fresh |

| Ignitor / Pilot | No flame, clicking attempts | Watch for a glowing ignitor or a steady pilot; cracked or unlit ignitors are common failures |

| Blower motor | Fan noise but weak airflow | Check the filter, listen for bearing noise, confirm blower runs only on a heat call |

This quick-reference helps you prioritize which checks to run first and which symptoms point to airflow, control, ignition, or blower issues. Next we’ll look closer at how dirty filters and thermostat faults reduce heating performance and what to do about them.

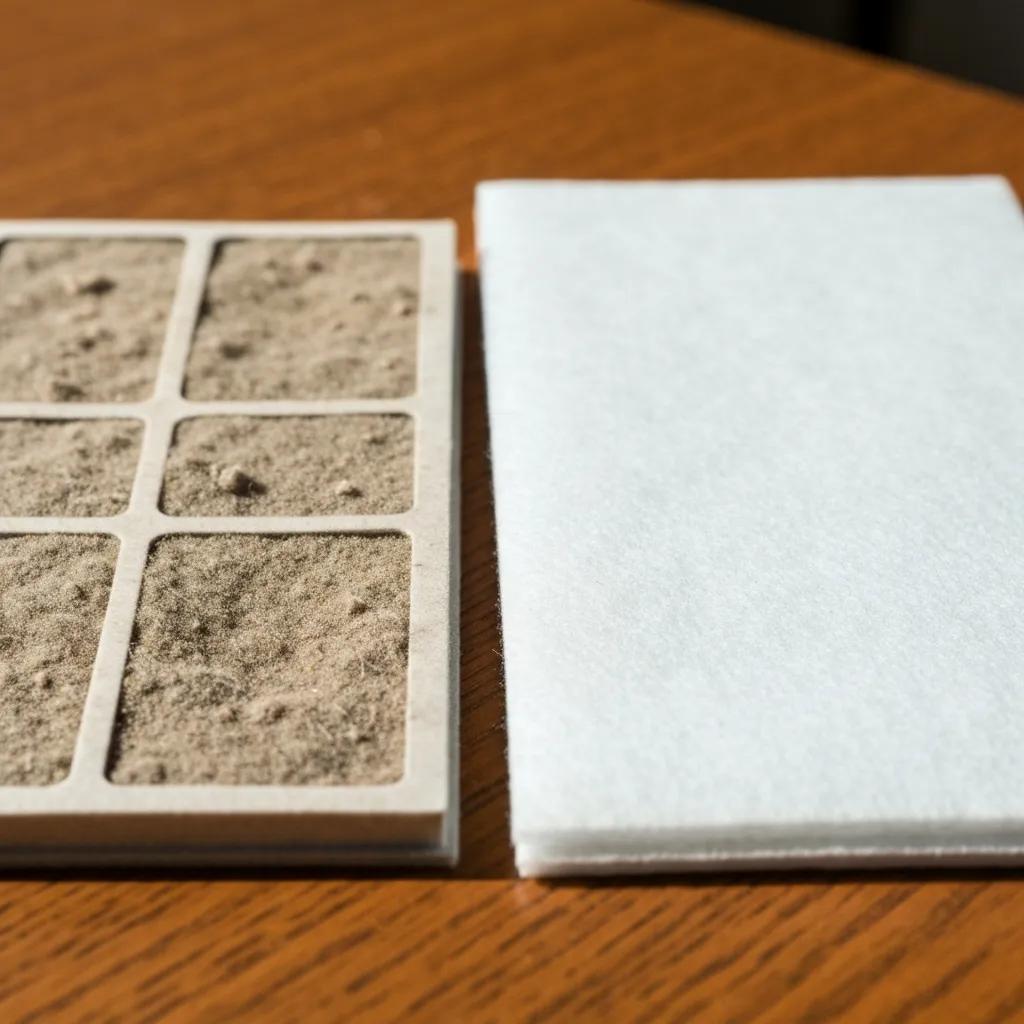

How Do Dirty Air Filters Affect Furnace Heating?

A clogged air filter chokes airflow through the heat exchanger. That lowers the heat delivered to your rooms and can make the furnace overheat and shut down on a limit switch. Restricted airflow also forces longer run times and stresses the blower motor. Replacing or cleaning the filter is a quick fix that often restores normal operation — signs include weak air at the registers and unusually long run cycles. After you change a filter, watch run time and check vent temperatures to confirm the furnace is heating properly again.

How Can I Troubleshoot a Furnace That Blows Cold Air?

If the furnace runs but only blows cold air, ask whether the blower is running without combustion or if burners are lighting but the heat isn’t transferring. Common culprits include the thermostat fan set to “On,” a blocked filter pulling cold return air, a failed ignitor or pilot, a dirty flame sensor, or an interrupted gas supply. Use a safety-first, step-by-step approach to see whether the unit is trying to heat but failing (combustion issue) or simply circulating unheated air (airflow/control issue). Follow the checklist below to troubleshoot cold-air blower situations safely.

Follow these steps in order to diagnose cold-air blower conditions:

- Check thermostat settings: Make sure the system is in “Heat” and fan is set to “Auto” not “On”.

- Inspect and replace the air filter: A clogged filter can drastically reduce heat transfer.

- Listen for ignition attempts: Clicking, hissing, or a brief burner light means the system is trying to ignite.

- Verify pilot or ignitor operation: Older systems use a pilot; newer ones use a hot-surface ignitor that should glow on startup.

- Confirm gas supply and safety lockouts: If you smell gas or suspect interrupted supply, evacuate and call professionals.

These ordered steps separate easy homeowner fixes from hazards that demand professional attention. The next table shows common DIY checks, the risks involved, and when to stop and call a technician.

| Component | DIY Check | Risk / When to Call |

|---|---|---|

| Blower / Fan | Confirm fan runs only on a heat cycle; check filter | Call a pro if the blower runs but airflow is weak despite a clean filter |

| Gas supply / Pilot | Check gas valve position and look for a steady pilot (if present) | Evacuate and call a pro if you smell gas |

| Flame sensor | Note flame quality; clean the sensor if safe to do so | Call a pro if the flame is unstable or the sensor keeps shutting burners down |

| Air filter | Replace if dirty | Replace immediately; repeated clogging could point to duct or airflow issues |

These checks help you decide whether the furnace has a combustion failure or is only circulating cold air, and they set clear safety limits before attempting deeper diagnostics.

What Steps Should I Take to Check the Furnace Fan and Blower Motor?

Start by confirming the blower runs only when the thermostat calls for heat; if it runs constantly, check the thermostat’s fan setting. Remove the filter and look into the blower area for debris, belt wear (if present), or loose wiring — always shut power off before touching anything. Listen for grinding, squealing, or humming that suggests bearing or capacitor problems, and note any slow or intermittent spinning. If the motor hums but the fan won’t start or draws too much current, that’s a job for a licensed technician to test and repair.

How Do I Verify Gas Supply and Pilot Light Status?

For furnaces with a standing pilot, visually confirm the pilot flame is steady and blue; a weak or yellow flame can mean combustion issues or a clogged pilot orifice. For electronic ignition systems, listen for ignition attempts and, if safe, check for burner flame through an access port. If the unit repeatedly fails to ignite after control attempts, the ignitor may be bad or the gas valve could be locked out. If you smell natural gas, evacuate immediately, avoid switches or open flames, and call emergency services and a qualified technician — do not try to relight a pilot in that situation. When the gas supply is suspected to be interrupted by the utility or a shutoff, let a professional restore service safely.

Why Is My Furnace Not Igniting or Starting Properly?

Ignition and start-up failures usually point to the ignitor or pilot assembly, the flame sensor, the control board, or a safety interlock like the limit switch. A cracked hot-surface ignitor or a pilot that won’t stay lit prevents burners from producing heat. A dirty flame sensor can falsely report no flame and shut the burners down. Electrical problems such as a failing control board or transformer also stop normal start sequences and require diagnostic tools. Below are homeowner checks and an explanation of why many ignition problems need a pro for safe, accurate repair.

How Can I Diagnose Ignition System Failures?

First identify whether your furnace uses a standing pilot or an electronic ignitor — that determines what checks are safe. For a standing pilot, confirm flame shape and brightness. For hot-surface ignitors, look for the element to glow during startup and never touch it. A dirty flame sensor typically causes short-run cycles where the burners light briefly then shut off; carefully cleaning the sensor with fine steel wool can help if power is isolated and you follow safety steps. If the control board repeatedly cycles without successful ignition, or the ignitor is visibly cracked, replacement by a trained technician is usually required.

What Does It Mean When the Furnace Short Cycles or Shuts Off Early?

Short cycling — when the furnace runs briefly and then shuts off repeatedly — lowers efficiency and increases wear. Common causes include overheating from restricted airflow (dirty filter or closed vents), blocked or undersized ductwork, a failing limit switch, or an oversized system that reaches setpoint too fast. Short cycling often shows as rapid on/off cycles and may produce error codes on modern control boards. Because short cycling involves safety controls, a professional airflow and component assessment is usually the right next step. Don’t rely on temporary fixes that mask a worsening problem.

When Should I Call a Professional for Furnace Repair or Replacement?

Knowing when to call a pro avoids safety risks and wasted time. Call immediately if you smell gas, notice electrical burning smells, see persistent flame instability, have repeated short cycling, find a non-spinning blower that hums, or face control-board error codes. For repair-versus-replace decisions — for example when multiple components fail or efficiency is poor — a licensed technician can assess the heat exchanger, ductwork, and long-term costs. Below are red-flag scenarios that deserve an immediate professional response.

Situations that require professional intervention include:

- Smell of gas or suspected leak: Evacuate the home and call emergency services and an HVAC pro.

- Electrical burning or frequent tripped breakers: Stop using the unit and bring in an electrician or HVAC technician.

- Repeated short cycling or safety shutdowns: Professional airflow and control diagnostics are needed.

- No ignition with control-board error codes: Advanced diagnostics and parts replacement should be handled by a licensed tech.

These red flags prioritize safety and indicate issues beyond safe homeowner troubleshooting. The table below explains common problem categories that typically need a licensed technician and why professional tools and training matter.

| Repair Category | Technician Tasks | Risk of Delay |

|---|---|---|

| Gas-related faults | Leak detection, gas valve testing | Explosion or carbon monoxide risk |

| Electrical/control faults | Control board diagnostics, multimeter testing | Fire risk, system lockout |

| Heat exchanger concerns | CO testing, visual inspection | Carbon monoxide exposure, catastrophic failure |

| Blower/motor replacement | Motor testing, capacitor checks | Further motor damage, poor airflow |

When these problems appear, a certified technician protects safety and ensures repairs comply with local codes and manufacturer guidelines. Puckett’s Heating & Air serves Maryland and Delaware and can diagnose these issues and recommend repair or replacement based on measured results.

What Furnace Problems Require Expert HVAC Technician Help?

Major gas issues, suspected heat exchanger cracks, large electrical faults, sealed combustion access, and repeated control-board errors should be handled by licensed pros. Those jobs require calibrated instruments — combustion analyzers, CO detectors, and multimeters — plus knowledge of local codes and safety protocols. Delaying professional service can raise the risk of carbon monoxide exposure, fire, or complete equipment failure. If simple homeowner checks (filter, thermostat, breakers) don’t bring the furnace back, schedule a professional inspection.

How Does Puckett’s Heating & Air Support Furnace Repair and Replacement in Maryland and Delaware?

Puckett’s Heating & Air works with homeowners and small commercial clients across Maryland and Delaware on furnace repair, replacement, installation, and preventative maintenance with a whole-system focus. Our technicians evaluate duct systems on every call and hold certifications like BPI, Energy Star Rater, HERS Rater, and NCI for air balancing. We provide transparent pricing and financing options to help you weigh repair versus replacement when diagnostics show multiple failures or poor efficiency. To schedule an on-site evaluation or learn about maintenance plans, contact Puckett’s directly for a written recommendation tailored to your system and home.

Frequently Asked Questions

What should I do if my furnace is making unusual noises?

Strange noises — grinding, squealing, or rattling — often signal mechanical problems. Grinding can mean worn bearings or a failing motor; squealing may be a slipping belt; rattling could be loose parts or debris. Turn off the furnace and do a visual check if it’s safe. If the sounds continue or you’re unsure what you see, call a professional technician to diagnose and repair the issue safely.

How can I improve my furnace's efficiency?

Start with simple steps: replace or clean air filters every 1–3 months, seal duct leaks to prevent heat loss, and consider a programmable or smart thermostat to match heating to your schedule. Scheduling annual professional maintenance keeps burners and controls tuned and helps catch small problems before they hurt efficiency. These steps lower energy bills and keep your system running better longer.

What are the signs that my furnace needs to be replaced?

Replacement may be the right choice if your furnace is more than 15 years old and needs frequent repairs, if heating is inconsistent, if energy bills are rising, or if you hear unusual noises or detect smells. Short cycling and failure to maintain set temperature are also warning signs. A professional inspection can compare repair costs versus replacement and recommend the most cost-effective path.

Can I perform furnace maintenance myself?

Yes — homeowners can handle basic tasks like replacing or cleaning filters, checking thermostat settings, and clearing vents. But more complex jobs, such as cleaning burners or testing electrical components, should be left to professionals for safety and code compliance. Do what you can safely, and call a tech for anything beyond basic checks.

What should I do if I smell gas near my furnace?

If you smell gas, act immediately: get everyone out of the building, avoid using electrical switches or open flames, and call your gas company or emergency services from a safe location. Do not try to troubleshoot or relight anything — gas leaks are dangerous and require professional handling.

Conclusion

Knowing the common causes of a furnace that won’t heat helps you act quickly and safely. Start with simple checks — filters, thermostat settings, and breakers — and use the step-by-step guidance here to narrow the problem. If those steps don’t restore heat, or if you encounter gas smells, electrical issues, or repeated safety shutdowns, call a licensed technician. For dependable furnace repair, maintenance, or replacement in Maryland and Delaware, Puckett’s Heating & Air is ready to help keep your home comfortable and safe.